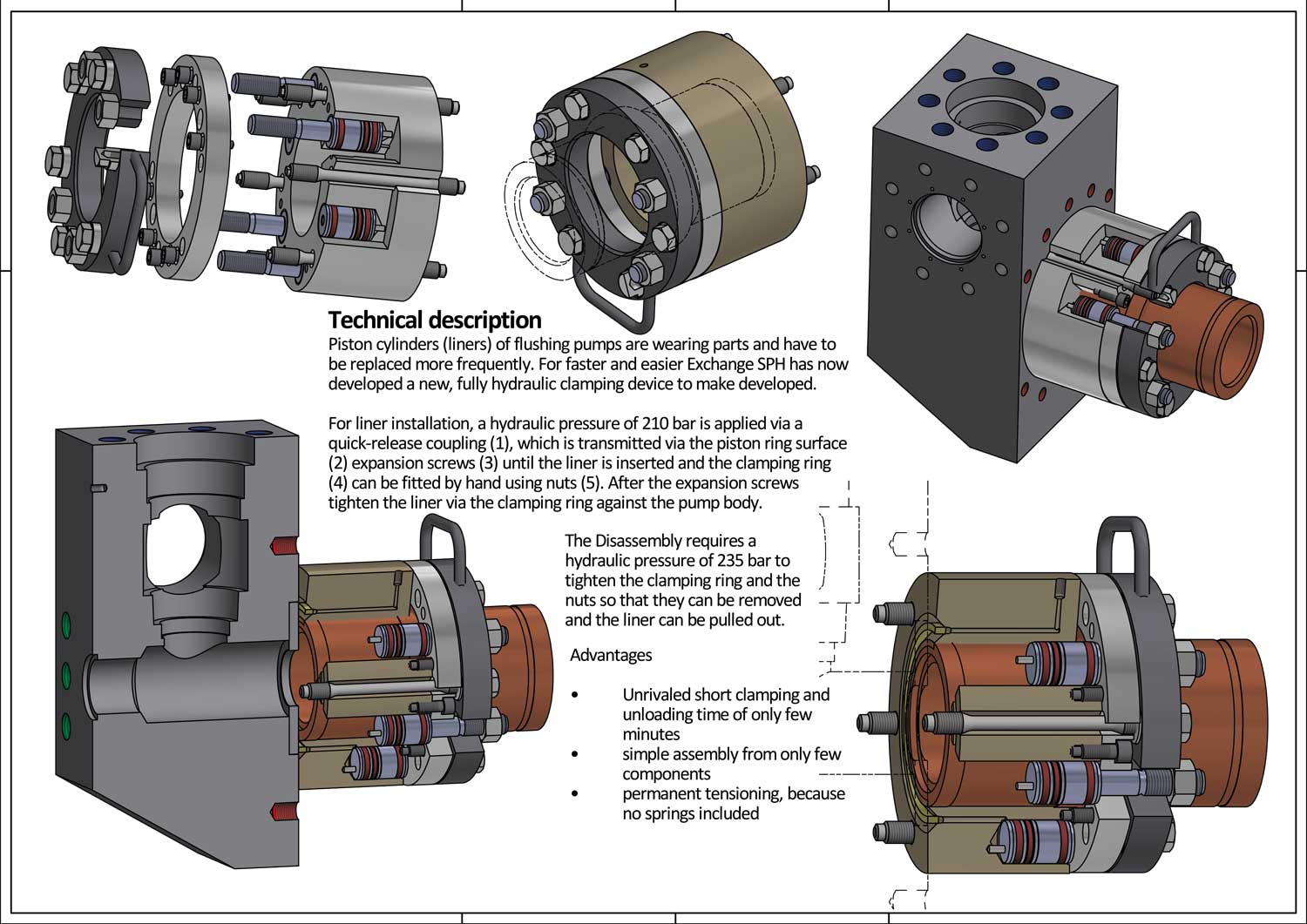

Liner tensioning device and tensioning clamp combined

Good as new in no time at all

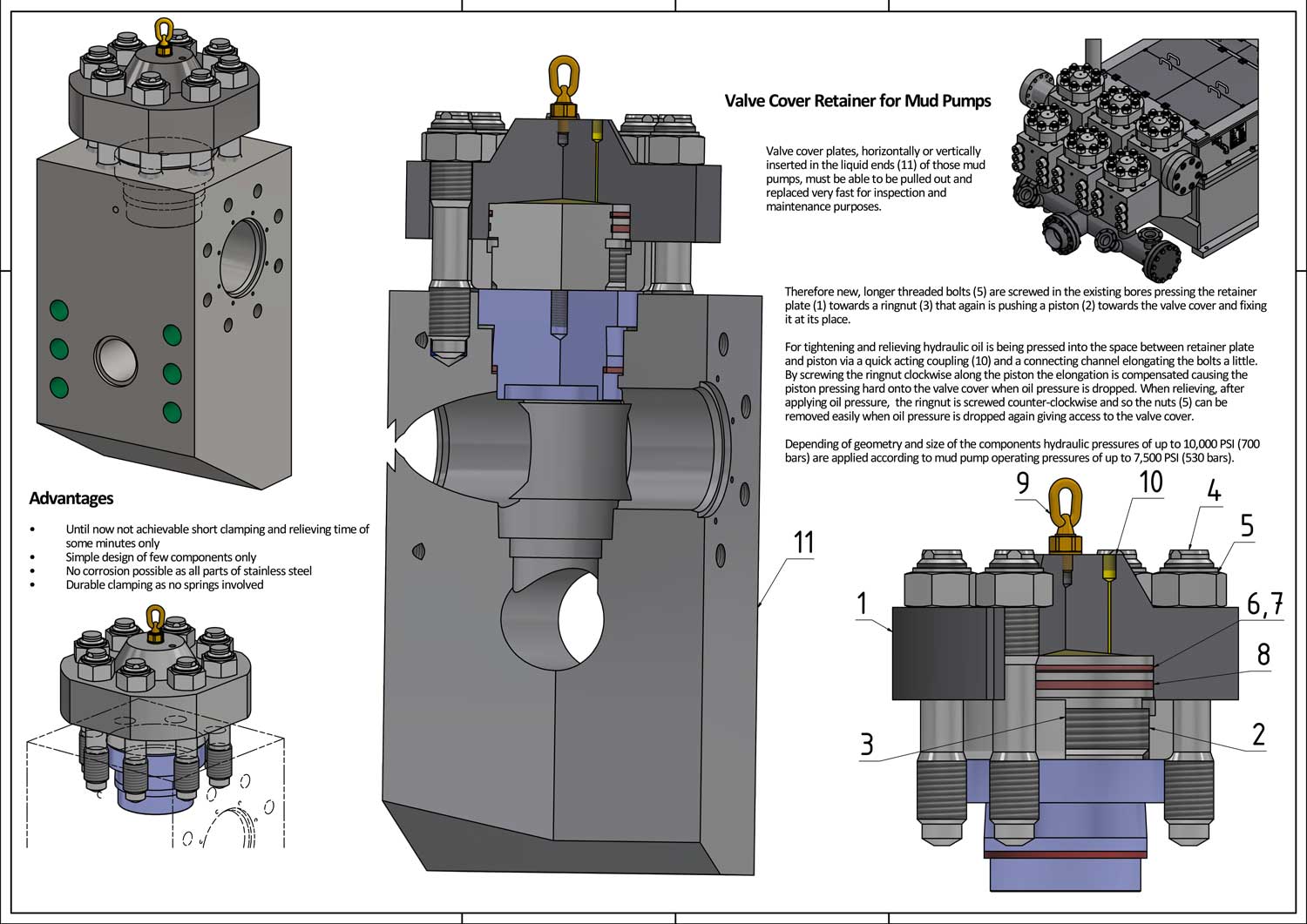

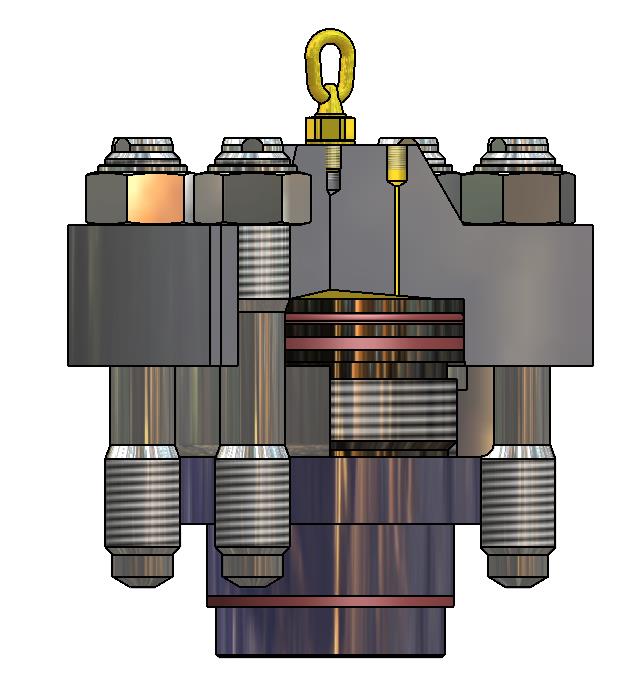

As part of our commitment to providing customers with the very latest technological advances, Schäfer Pumpen & Hydraulik has developed an innovative, fully hydraulic tensioning device for the rapid replacement of worn mud pump liners and valves. Once a hydraulic pressure of 235 bar is generated, it’s easy to remove worn liners. After a new liner has been inserted and the pressure released, the liner is pulled tight against the pump body via the tension ring. For valve caps, it’s simply a matter of creating oil pressure to lengthen the bolts and turn the ring nut up against the tensioning cap. When the oil pressure is released, the nuts can be easily unscrewed.

Unique features

- The first device with tensioning and release times of just seconds

- Simple construction with minimal components

- Easy to operate

- Tension ring can be bolted manually

- Absence of springs allows for fatigue-resisting tensioning

Clamping Device

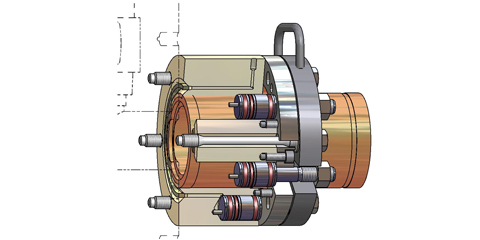

Piston cylinders (liners) of flushing pumps are wearing parts and therefore need to be replaced more frequently. For faster and easier replacement, SPH has developed a new type of fully hydraulic clamping device.

Advantages

unrivaled short clamping and unclamping time of only a few minutes

simple assembly from only a few components

permanent tensioning, as no springs are included

Find out more about our other special products:

Pumps and Pump Units

Schäfer Pumpen & Hydraulik’s industrial pumps and pump units are a global success story thanks to three key features: reliability, strength, and superior quality.