Mining

This keeps the tunnel safe

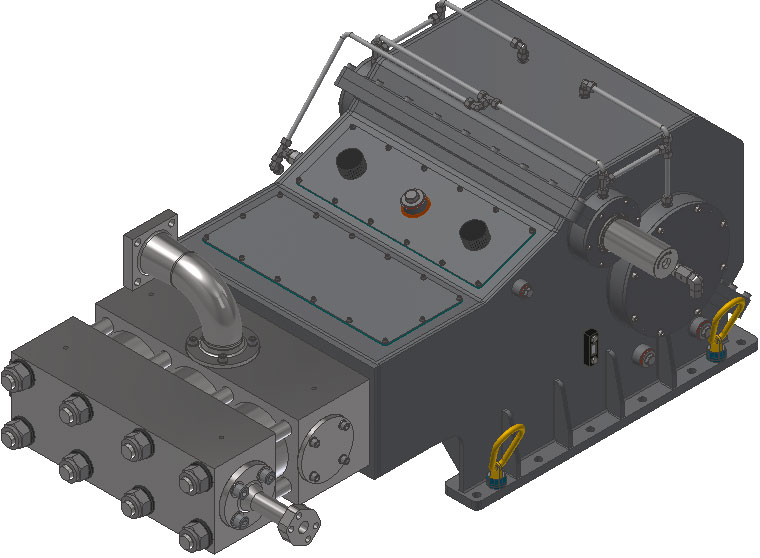

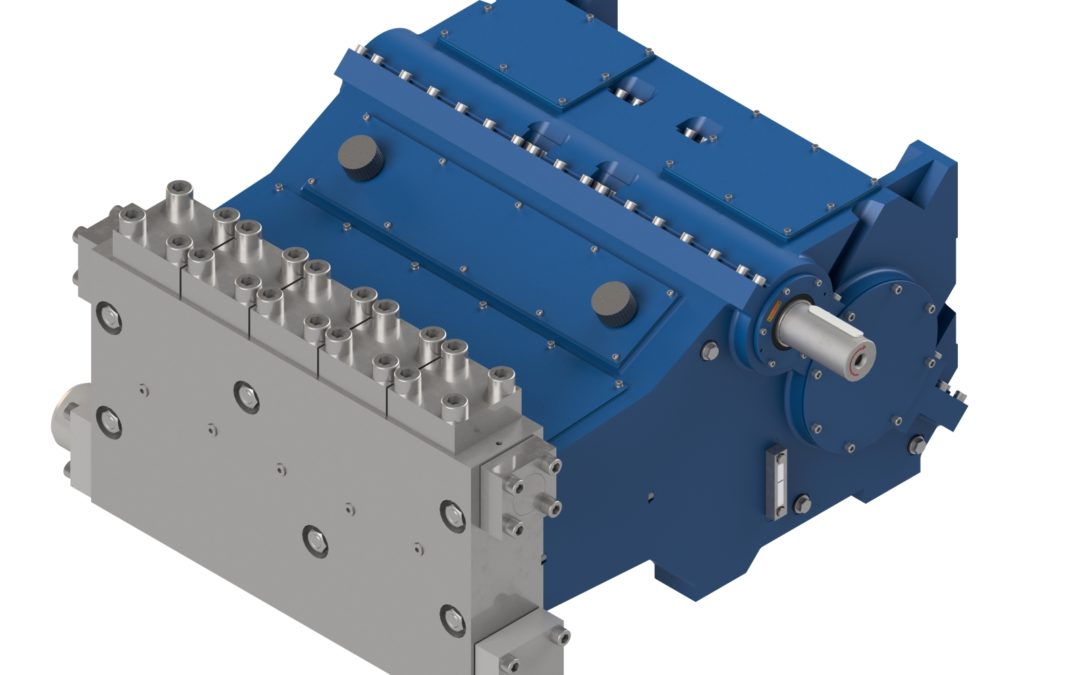

Schäfer high-pressure pumps for hydraulic face operations

In hydraulic face operations, piston pump units are in use all over the world. For the highly challenging conditions in underground mining we offer an extremely sturdy and user-friendly high-pressure pump for the high-capacity range.

Another field of application is hydraulic coal mining.

All pumps are very compact and sturdy, specifically designed to cope with the conditions of underground mining. Moreover, they are extremely service-friendly.

Drive unit

- sturdy and compact

- designed for long-time continuous operation

- FEM-calculated components

- ball joint, extremely smooth operation

- four-bearing crankshaft featuring bearings made by European manufacturers

- integrated gear unit with helical-toothed drive shaft

- external dual-cycle forced lubrication for speed-controlled pumps

- two-part, diagonally separable drive unit housing, easy maintenance

Fluid end

- high volumetric flows at moderate speeds; extended lifetimes of all wear parts at the fluid end and in the exchange set

- service-friendly design, e.g. no grouted valve seats

- monobloc design made of high-strength, corrosion-resistant forged steel

- composite ceramic piston with innovative, hydraulically reinforced piston sealing

The new HDP series is a further development of the well established Schäfer high-pressure pumps. They have been specially adapted to meet the challenging requirements of the mining industry. HDP 315, HDP 500 and HDP 1000 are of an extremely robust and compact design. Our emphasis in the redesign was on the drive equipment. The components subject to high dynamic stress have been FEM-designed and are suitable for long-time, continuous operation. The extremely rigid crankshaft is made of a high-strength steel alloy.

A highlight of our pumps is the ball joint in the sliding sleeve. The ball ensures low-friction, play-free force transmission. Due to the large transmission area, the ball joint is virtually maintenance- and wear-free. Expanded degrees of freedom prevent forced guiding and any lateral forces. The most obvious positive result is the extremely smooth-running pump drive.

Introduction of force is via a solid, double helical-toothed gear integrated into the drive unit and driving the crankshaft, which is supported by four bearings. To guarantee extremely long lifetimes, we use only quality bearings made by European manufacturers in our pumps.

Safe cooling and lubrication are provided by an external dual-cycle pressure lubrication system.

The lubrication system is designed to ensure reliable oil supply over the complete speed range.

Thanks to the diagonally separable housing of the drive unit, the drive components are easily accessible for assembly or maintenance activities.

The pump head is likewise of a very compact design. To optimize the flow geometry, the suction and pressure valves are arranged one above the other in one row. Despite the high volumetric flows, the service lives of the valves and seals are very long last but not least to the moderate pump speed. The valve column is also of a very service-friendly design. For example, as there are no grouted valve seats, the complete valve column can be quickly removed or individual valves can be replaced in no time. The pump head of monoblock design, made of high-strength, corrosion-resistance forged steel meets most exacting requirements. All water-guiding parts are made of high-quality stainless steel. A special highlight are the exchange sets with composite ceramic pistons. Their innovative, hydraulically self-reinforcing piston seals provide long lifetimes, guarantee quick changing and reduce the operators’ total cost of ownership.

Where products from Schäfer Pumpen & Hydraulik are used in the mining industry:

Coal liquefaction – A breakthrough process in the fuel industry

Coal liquefaction for the production of liquid products (from gasoline to heavy fuel oil) from coal take place basically via two process routes: Direct hydration of the coal and coal gasification with subsequent (indirect) hydration of the synthesis gas and indirect coal liquefaction via synthesis gas. In 1925, the process was patented by Fischer and Tropsch. Until 1945, both processes were used in Germany for large-scale industrial coal hydration. Schäfer Pumpen & Hydraulik offers recirculation and injection pumps for both processes.

Application of Schäfer Pumpen & Hydraulik Products in Mining:

High Pressure Pump FR

Presentation of our new development of the Triplex Plunger Pump The high pressure pump type Fr 800-140 is a new development of the triplex plunger pumps in horizontal design for underground fracking applications. It is a triplex pump with 3 crankpins offset by 120°...

High-pressure Pumps HDP

The portfolio of Schäfer Pumpen & Hydraulik includes a new, innovative series of high-pressure pump systems.